MED-Pack eco

The compact design of MED-Pack eco significantly reduces packaging volume. The integrated product fixation adapts to the product size and ensures optimum protection – abrasion or damage caused by movement inside the packaging is thus reliably prevented. In the operating theatre, the 'no-touch' design enables safe and hygienic removal without direct product contact and without the risk of cut gloves.

Applications

Advantages

Opening procedure in the operating room

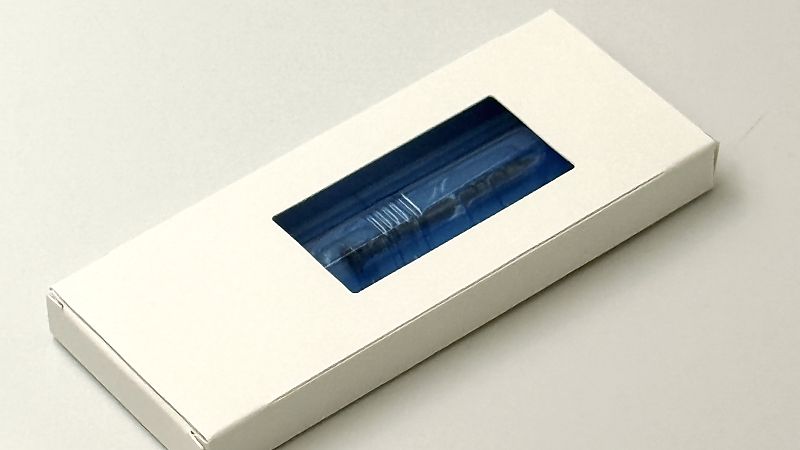

Peeling/bending of secondary packaging

1.1

Removal of primary packaging from secondary packaging

No contact with secondary packaging by person removing it (no touch)

Peeling/bending of the primary packaging

2.1

Removing the MEDPUR pack from the primary packaging

No contact with the primary packaging by the person removing it (no-touch)

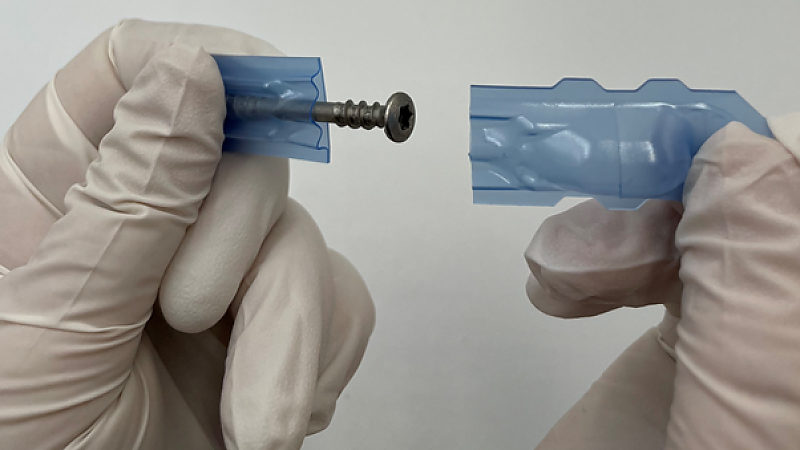

Opening/separating the MEDPUR-Pack

3.1

Removing the screw with the screwdriver

The MEDPUR-Pack protective packaging prevents cuts and damage to gloves. The screw can be removed without touching it (no touch).

Packaging process in the clean room for MED-Pack eco

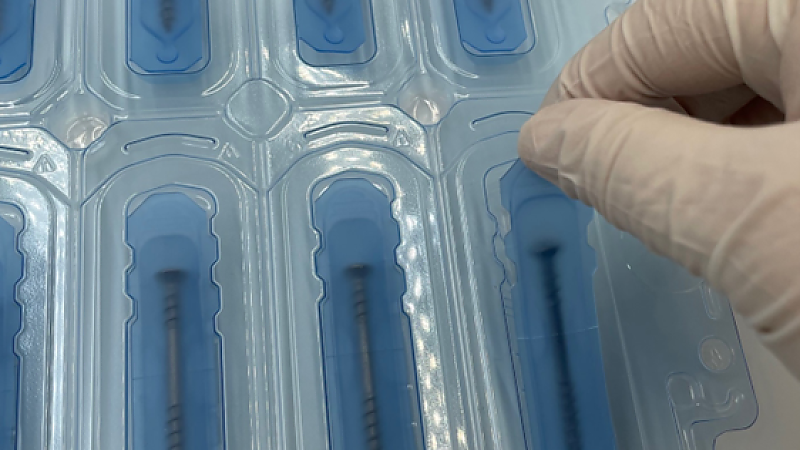

Inserting the screw into the MEDPUR pack

Inserting the MEDPUR pack with screw into the primary packaging

2.1

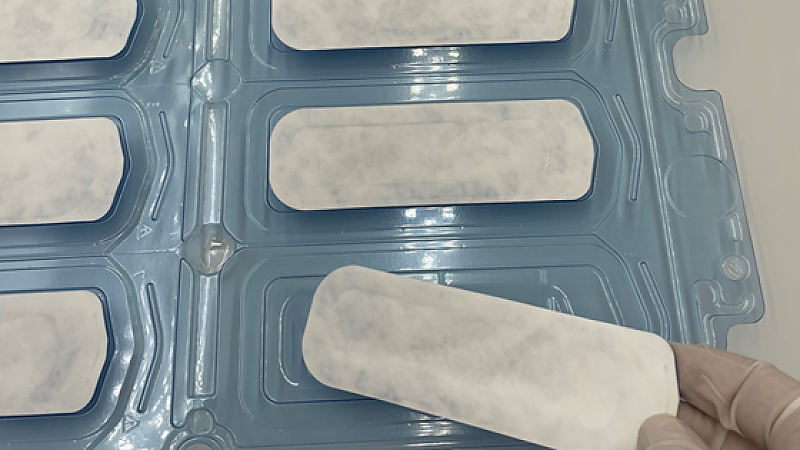

Sealing (with Medipacker TS heat sealing machine) of the primary packaging with sealing lid (sealing lid can be pre-printed if required)

2.2

Separation (with ZSM punching machine) of the multiple sheet for the primary packaging

Inserting the separated primary packaging into the secondary packaging

3.1

Sealing (with Medipacker TS heat sealing machine) of the secondary packaging with sealing lid (sealing lid can be pre-printed if required)

3.2

Separation (with ZSM punching machine) of the multiple sheet for secondary packaging